金屬密封浮動(dòng)、固定式球閥

ANSI VI 級(jí)密封性能 采用先進(jìn)的球體研磨工藝球體和密封面達(dá)到極高的圓度和光潔度。

球體和閥座硬化技術(shù) 超音速?lài)娡俊㈡嚮鶉姾浮⒂操|(zhì)合金噴焊、高強(qiáng)高硬陶瓷加工的球體和閥座,表面硬度達(dá)到HRC60~74,耐溫540℃,最高980℃。

防止閥門(mén)高溫時(shí)脹卡 采用專(zhuān)利技術(shù)高溫時(shí),零部件膨脹量,由特殊結(jié)構(gòu)吸納,使開(kāi)關(guān)靈活。

密封緊急救護(hù) 高壓固定式球閥帶有密封注脂孔,可修補(bǔ)密封面,保證密封還可清洗閥腔密封面。

ANSI VI Leakage Advanced ball skiving craft, between the ball and the seal face, there appears roundness and cleanness.

Vulcanize techniques on ball and seat ring HRC60~74 on the surface, 540℃-980℃

Prevent bulge when meet high temperature Adopts patent technical, the bulge of the parts was absorbed by special machinery, open and close flexibly

Repair seal the seal face can be repaired

☆固定球閥球前雙向密封 ☆球腔內(nèi)超壓釋放功能 ☆自然防靜電結(jié)構(gòu) ☆防火安全設(shè)計(jì)

Double directions seal pressure relief prevent static structure Fireproofing design

|

|

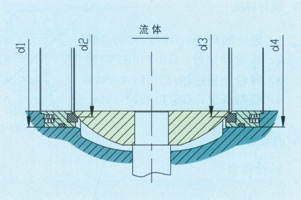

密封性能可靠(見(jiàn)圖一):PTFE彈性材料密封圈嵌于不銹鋼閥座內(nèi),金屬閥座尾端設(shè)有彈簧保證密封圈足夠的預(yù)緊力,閥門(mén)在使用過(guò)程中密封面磨損時(shí),在彈簧作用下閥門(mén)繼續(xù)保證良好的密封性能。

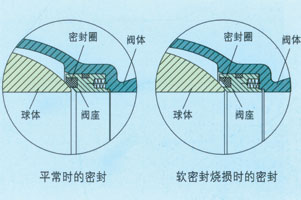

防火結(jié)構(gòu)(見(jiàn)圖二):為防止由于驟熱或火災(zāi)的出現(xiàn),使聚四氟乙烯密封圈燒毀,發(fā)生較大泄露,而助長(zhǎng)火勢(shì),在球體與閥座間設(shè)置防火密封環(huán),在密封圈燒毀時(shí)在彈簧力作用下,將閥座密封環(huán)迅速推向球體上,形成金屬與金屬密封,起到一定程度的密封效果。耐火試驗(yàn)符合API 6FA和API 607標(biāo)準(zhǔn)要求。

Seal is reliability (Picture one): PTFE O-ring was set in stainless steel seat ring, and there is spring at the end which makes the seal ring have enough tighten. Under the action of the spring the valve still has a good seal when the seal face is abrade.

Airproofing structure(Picture two):In order to prevent heat and fire from burning Teflon which makes leakage, fostering fire, we set fireproofing seal ring. When the seal ring was burnt, at the action of the spring, it drives the seal ring to the ball which makes the metal touches with each other. Fireproofing testing comply with API 6FA and API 607

|

|

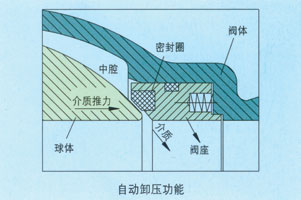

自動(dòng)泄壓功能(見(jiàn)圖三):當(dāng)閥門(mén)中腔停滯的介質(zhì)壓力異常升高超過(guò)彈簧的預(yù)緊力時(shí),閥座后退脫離球體,達(dá)到自動(dòng)卸壓的效果,卸壓后閥座自動(dòng)復(fù)位。

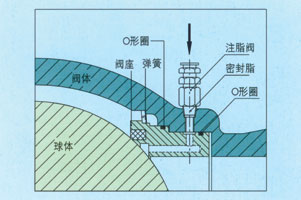

可修補(bǔ)密封面(見(jiàn)圖四):本閥門(mén)設(shè)計(jì)有輔助的閥座緊急密封系統(tǒng),一旦密封受損或出現(xiàn)緊急情況而不能密封時(shí),通過(guò)輔助密封系統(tǒng)向密封面注射相應(yīng)的密封劑即可修復(fù)密封面,達(dá)到緊急密封。當(dāng)輸送的介質(zhì)不潔或含有少量顆粒時(shí),為保護(hù)密封面,確保達(dá)到可靠的密封,還可給這一裝置注射相應(yīng)的清洗劑或潤(rùn)滑劑對(duì)密封面進(jìn)行清洗。

Pressure Relief Automatically (Picture three):When the pressure inside the valve is much higher which exceeds the spring’s power, the valve seat is back ,breaking away from the ball. The pressures can relief automatically. At the same time, the seat is able to return automatically.

Seal face can be repaired (Picture Four): This kind of valve has assistant seal system. In case of emergency or the seal is damaged, the assistant seal system can repair the seal face. When the operating medium contains some granules, you can squirt lotion or lubricant to clean the seal face, making sure a reliable seal.

|